What Are The Basic Tools Required For Bead Making?

This tutorial will provide an overview of the basic tools required to start lampwork bead making. It is designed as a beginners guide, and greater detail will be provided in later updates.

A Safe Working Area

Before you purchase any items, you will need a safe operating area. Lampwork bead making will involve a naked flame, fuel sources and hot glass - your front room may not be the safest place to setup! You will need to consider the following points:

|

Ventilation. A flow of fresh air will be needed to remove the irritant gasses and particles generated when using a flame, such as Nitrogen Oxide & Dioxide, Carbon Monoxide & Dioxide. These by-products can cause severe irritation to your respiratory system and should be removed from your working area immediately. Ideally, an extraction system should be used, but if this is not possible, then you should (at least) open several windows and ensure a constant flow of air is available in your working area.

Flameproof Work Surface. Should hot glass fall onto your table, you must ensure that the surface it falls on will not catch fire. A stainless steel sheet or granite tile is ideal. |

Types Of Torches, Fuel & Oxygen Sources

|

Once you have decided where you are going to work, you must decide how you are going to work - what type of torch will I need?

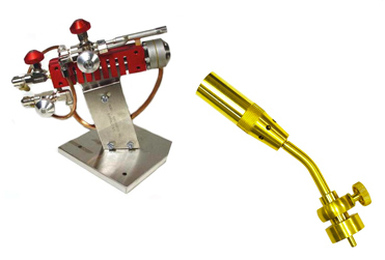

You can buy a good Hot Head starter kit from the UK based company Tuffnell Glass for a little over £100. This is a lot like working with a large Bunsen Burner as there is no additional oxygen required. The Hot Head can be slower to work with but those that use them are often passionate about them! I currently use a Nortel Minor Burner, also available as a kit from Tuffnell Glass, this is a more costly set up at over £500. However, it included everything I required to make beads for well over 6 months, before I decided to invest in my annealing kiln to complete my studio set-up. |

Essential Lampworking Tools

|

The essential tools & equipment you will need to make your own glass beads are:

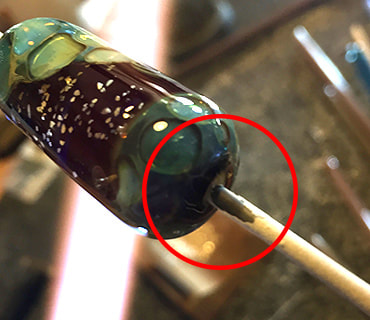

Mandrels. Mandrels are metal rods available in various shapes and sizes. Molten glass is applied to the mandrel, which is then turned in the flame to form a glass bead. Naturally, a 5mm thick mandrel will leave behind a 5mm hole in the bead. Bead release is a liquid solution that stops glass beads from permanently sticking to the metal mandrel. Mandrels are dipped into bead release, and then dried overnight or immediately in the flame - depending on the brand of bead release. To remove the bead from the mandrel, you soak it with water, which then causes the bead release to 'flake away', allowing you to wiggle and slide the bead off. |

|

Glass rods are melted to form a bead. They are sold in a variety of colours and thicknesses which allow you to create beads with different patterns and designs. You must be careful when mixing glass, as not all glass is compatible, which can result in cracking. Visit my types of glass guide for further information.

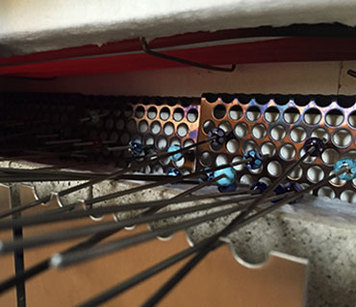

Fire extinguisher. Ensure you choose one that is suitable for your surroundings (most likely Water / Class A), and know how to use it! Cooling system. When glass is cooled too quickly, stress fractures can occur, leading to cracks and broken beads. To prevent this from happening, the glass must be cooled slowly and in a controlled manner. The cheapest methods are cooling bubbles and fibre blankets, but these methods will not anneal your beads, meaning that they could still crack - using a kiln is the only way you can be sure that your glass has been annealed correctly. Didymium glasses protect your eyes from the flare of the flame and from any hot glass fragments should the glass shatter. |

Optional Extras

|

Marver. A marver is a flat heatproof tool or surface used to shape the glass. It is typically made from brass or graphite and can be attached to your torch or held in the hand.

Rod rest. This is normally a metal frame used to hold your hot glass rods as they cool. If you do not wish to buy a purpose made tool you can make your own, as long as it is heatproof and stops the glass from rolling around on your desk. Bead rollers and Presses. These are used to add shape and texture to warm, malleable glass, allowing you to create shapes and designs other than round beads, or they can be used to ensure you make similar sized and shaped beads to create a matching set. They are normally made from brass or graphite. |

|

Rakes and Pokers are sharp metal tools used to manipulate the surface design of the bead. By dragging or introducing indentations to the surface of a hot glass bead, swirls, bubbles and feathering can be added to the design. More expensive tools are made from Tungsten, which is less likely to 'stick' to hot glass.

Tweezers and Pliers can be used to remove excess glass or debris from a hot bead, and for any other purposes where you would not want to use your fingers. Crafting tools and stainless steel cutlery are a very cheap way to build your glass tool collection. Rather than buy a bespoke, expensive crafting tool, some artists use spoons, knives or even metal clay forming tools when shaping their beads. Kiln. This is not an essential piece of kit when starting out however, if you are planning to sell your beads, then a kiln quickly becomes essential as it allows you to anneal your beads, otherwise there is a high risk of them cracking due to unrelieved stresses within the glass. |